Obtaining as much information about the roof as possible in advance is invaluable. A set of roof drawings or plans make moisture mapping much easier and a knowledge of the construction will make the job of calibration much faster.

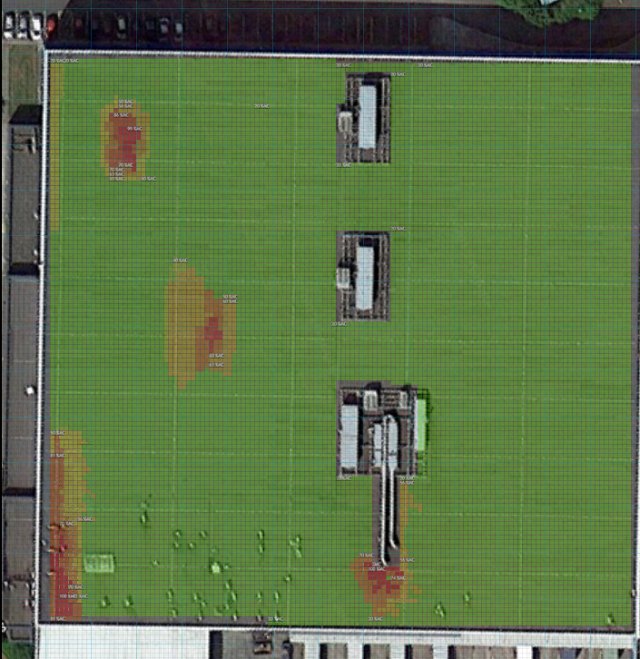

If a set of drawings or roof plan is not available, prepare a plan and report sheets for each section being surveyed or, better still, use the Tramex Moisture Mapping App. To perform a non-destructive flat roof moisture inspection to ASTM D7954 with the Dec Scanner, first ensure that the surface is free of debris and is dry from rain or dew. Aggregates may be left in place but should be dry and of uniform thickness. Once calibration and range selection is complete, proceed by moving the Dec Scanner along the imaginary gridlines in a continuous, systematic manner. The Dec Scanner is designed to cover the width of an average roll of roofing felt, making it simple to follow a systematic row-by-row methodology. Mark areas of concern onto the roof plan/Tramex Moisture Mapping App as well as directly onto the roof surface if required. Marking the surface directly can be helpful for finding the precise location for core samples later. Areas where the roof has non-uniform composition or thickness, such as areas which have been recovered or seams, should be tested and noted separately as they may provide different results. By continuously checking this way, a complete picture of the moisture condition can be built up quickly. An area of up to 100,000 sqft can be reasonably covered in one day.

Selected suspect wet areas should be confirmed by core sampling using gravimetric analysis in accordance with ASTM C1616. It is permitted to check core samples immediately after extraction with a pin-type resistance meter such as the Tramex PTM. An identified area of high moisture may also be checked with extended insulated resistance pins before core sampling, by first puncturing the surface of the roofing membrane with the Tramex Hole Punch and then with the Tramex hand held resistance probe – together with 7" or 15" insulated pins – insert the pins into the insulation for a further relative reading. These readings should be recorded on the report sheets to correlate with gravimetric measurements at the verification stage.